Quality

The RWT quality:

Certified work.

Only permanent quality assurance creates trust, which is why RWT is committed to this principle throughout the entire production process. We only supply you with components that meet clearly defined quality standards and are of the highest quality, designed for maximum performance on which you can rely on. We therefore implement strict and disciplined measures to ensure the high quality of our products.

In our company – certified according to DIN ISO 9001:2015 – great attention is paid to quality assurance. Measurements are taken on modern 3D measuring machines and measuring devices. All ground parts are tested with our magnetic particle crack testing machine.

Certified quality work

Since its foundation, RWT Hornegger & Thor GmbH has specialized in the production of parts at the highest level. Since 21.01.2000 we are certified according to DIN ISO 9001:2015.

Download certificate.

The test procedures at a glance

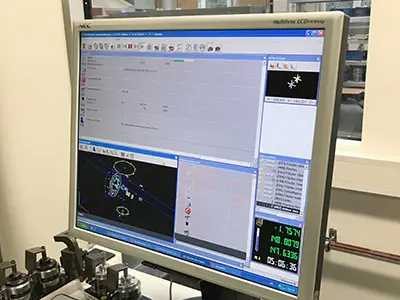

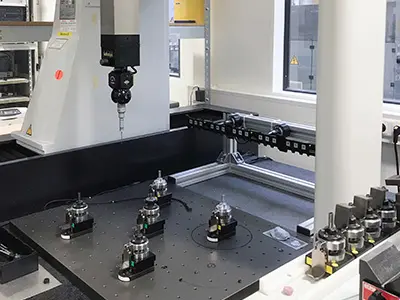

Global Advantage 3D coordinate measuring machine

B3C-LC 3-axis machine control; QUINDOS measuring software for Windows consisting of

Base – Camshaft

Curves and surfaces – Valve seat and guide

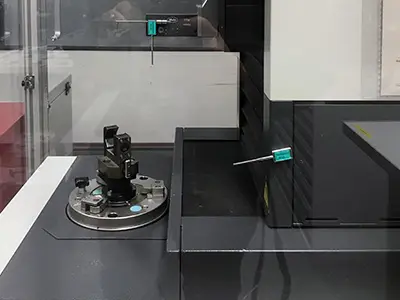

Mitutoyo 8 3D coordinate measuring machine

Trotec Speedy 360 Flexx

Laser engraving machine

Work surface

Width: 813 mm

Depth: 508 mm

Addressable accuracy:

5µm

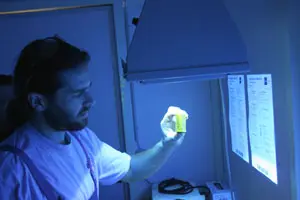

Magnetic particle crack detector Deutroflux EW 600

We also offer the option of testing all parts with

with our magnetic particle crack tester.

Mahr MarForm MFU 100

Evaluation of roundness, concentricity, axial run-out, concentricity, coaxiality, total concentricity, total axial run-out, cylindricity, straightness, parallelism, squareness, inclination and flatness.